The Facts About Premier Aluminum Llc Revealed

The Facts About Premier Aluminum Llc Revealed

Blog Article

Excitement About Premier Aluminum Llc

Table of ContentsThe Only Guide for Premier Aluminum LlcWhat Does Premier Aluminum Llc Do?5 Simple Techniques For Premier Aluminum LlcPremier Aluminum Llc Can Be Fun For Anyone

(https://dzone.com/users/5257665/premieraluminum.html)Commonly, a buyer's key duty was to discover qualified and responsive suppliers. In some situations, buyers assumed that any supplier eager to contractually satisfy the acquisition need was qualified. Nonetheless, utilizing affordable and unqualified distributors can trigger top quality issues, and squandered time and money in the lengthy run. To help you with the procedure, here are some things to take into consideration when choosing the ideal steel casting provider.

A business that only utilizes the investment casting process will certainly attempt to offer you on why that procedure is best for your application (Aluminum Casting company). What if utilizing the sand casting procedure is best for you and your demands? Rather, seek a supplier that offers a variety of casting procedures so the ideal alternative for YOU is chosen

If collaborating with a solitary source for all of your casting needs is very important to you, the distributor requires to be varied in its abilities. When integrated with other incorporated capabilities, this can help streamline and press the supply base. When picking the ideal casting distributor, mindful consideration ought to be given to top quality, service, and cost.

The Best Guide To Premier Aluminum Llc

Buyers significantly select spreading vendors who have machining capabilities. This can stay clear of dispute if issues are found during machining. If a 3rd party is machining, it might result in "finger-pointing" about that is at mistake. Is it a spreading problem or a machining issue? If the casting provider uncovers a problem throughout machining, the issue is dealt with faster without conflict over whose fault it is.

What do you require from your spreading provider? Are you looking for someone to just deliver a metal part to your front door or do you need more?

Others will certainly exceed the letter of the PO to help you conserve money and time. Do you have needs for both ferrous and non-ferrous alloys? Some foundries are minimal or specialized. Ensure the supplier can satisfy all your material or alloy requirements to remove the need for several vendors.

Indicators on Premier Aluminum Llc You Should Know

Research the provider's website. Talk to a sales representative or company associate.

Light weight aluminum is also light-weight and has good deterioration resistance, making it excellent for applications where weight and durability are crucial factors. Furthermore, light weight aluminum casting is a cost-effective approach of manufacturing, as it calls for much less energy and resources than other methods. Iron casting, on the other hand, includes putting molten iron into a mold to develop a desired shape.

The 15-Second Trick For Premier Aluminum Llc

Iron casting is likewise able to hold up against heats, making it ideal for use in applications such as engine parts and commercial equipment. Iron spreading can be a lot more costly than aluminum casting due to the greater price of raw materials and the power needed to thaw the iron. When determining in between light weight aluminum spreading and iron spreading, it is essential to consider the details demands of the application.

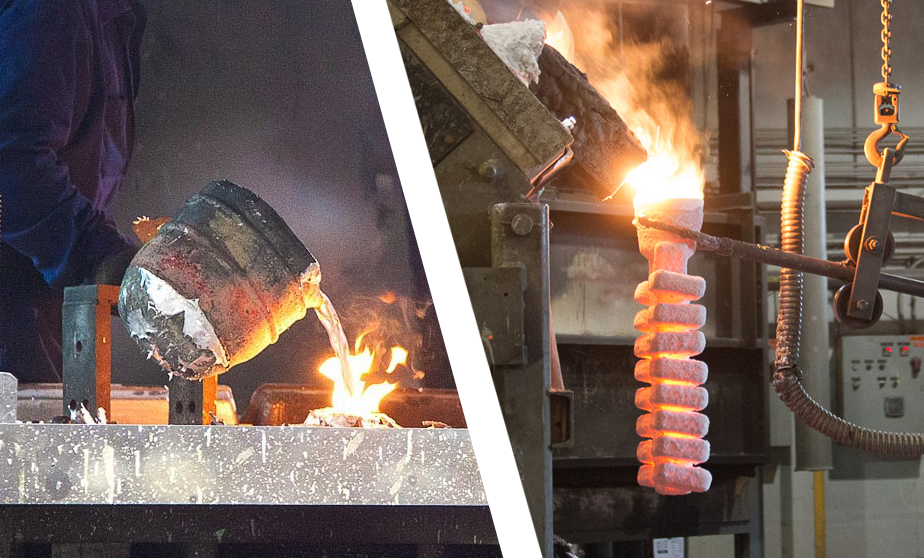

If toughness and sturdiness are more crucial, iron spreading may be the better option. Other variables to take into consideration consist of price, manufacturing volume, and lead time. In final thought, both aluminum spreading and iron spreading have their own unique benefits and negative aspects. By very carefully thinking about the certain requirements of the application, manufacturers can select the most effective procedure for their product.ZheJiang Dongrun Casting Sector Carbon Monoxide,. Ltd was constructed in 1995, We have actually been in the spreading industry for greater than 25 years. Pass away casting is the name offered to the

procedure of developing complex steel elements via usage of molds of the part, also recognized as passes away. The process utilizes non-ferrous metals which do not contain iron, such as aluminum, zinc and magnesium, as a result of the desirable residential properties of the metals such as low weight, greater conductivity, non-magnetic conductivity and resistance to deterioration. Die spreading production is quickly, making high manufacturing levels of elements simple.

It produces more parts than any kind of various other procedure, with a high degree of precision and repeatability. To get more information about die spreading and pass away casting products used at the same time, reviewed on. There are three sub-processes that fall under the classification of die spreading: gravity pass away spreading (or permanent mold and mildew spreading), low-pressure die casting and high-pressure die casting. The pure steel, also understood as ingot, is included in the heating system and maintained the molten temperature level of the steel, which is then transferredto the shot chamber and infused into the die. The pressure is after that maintained as the metal solidifies. As soon as the steel solidifies, the cooling process starts. The thicker the wall surface of the component, the longer the cooling time due to the quantity of interior steelthat also needs to cool. After the part is fully cooled, the die halves open and an ejection device presses the part out. Adhering to the ejection, the die is closed for the next injection cycle. The flash is the extra material that is cast throughout the procedure. This should be trimmed off making use of a trim device to

leave just the primary component. Deburring removes the smaller items, called burrs, after the cutting procedure. The component is polished, or burnished, to give it a smooth coating. This confirmed to be an imprecise examination, because the tester can cut right into an item and miss out on an area with porosity. Today, leading manufacturers use x-ray screening to see the whole interior of components without reducing right into them. This enables them to much more accurately approve or turn down parts. To reach the completed product, there are three key alloys utilized as die spreading material to choose from: zinc, aluminum and magnesium. Zinc is one of one of the most pre-owned alloys for die casting as a result of its reduced price of basic materials. Report this page